All stainless steel (shockproof) electric contact pressure gauge YXH (N) YXG (N) YXHD (N)

application The product is suitable for non viscous, non crystalline, and slightly corrosive gas and liquid media, measuring their pressure and vacuum. It is also used to control and regulate related industrial production processes, monitoring equipment, and control circuit on-off. It is widely used in industries such as petroleum, chemical, metallurgy, power, food, pharmaceutical environmental protection, machinery, etc.

Keywords:Ordinary pressure gauge、Shockproof pressure gauge

Category:

Product Description

application

The product is suitable for non viscous, non crystalline, and slightly corrosive gas and liquid media, measuring their pressure and vacuum. It is also used to control and regulate related industrial production processes, monitoring equipment, and control circuit on-off. It is widely used in industries such as petroleum, chemical, metallurgy, power, food, pharmaceutical environmental protection, machinery, etc.

technical parameter

Nominal diameter: D63mm, D100mm, 150mm Accuracy level:

Indication accuracy

φ 63mm Grade 2.5

φ 100mm Grade 1.0, 1.6, 2.5

φ 150mm Grade 1.0, 1.6

Setting accuracy level 4

Measurement range: -0.1~0~0.1... 100MPa

Or other equivalent pressure vacuum range

Environmental temperature- 40 ℃~70 ℃

Medium temperature: -40 ℃~100 ℃

When the temperature of the measurement system deviates by 20 ± 5 ℃. The change in setting error shall not exceed 0.02/℃

Process connection: M20 × 1.5, 1/2 "NPT, G1/2"

Customizable according to user requirements

Pressure sensing element:

<10MPaC-type pipe

≥ 10 MPa spiral tube

Liquid receiving material: 316L (or Monel optional) Case material: 304SS (or 316L optional) Movement material: 304SS

Instrument pointer: aluminum alloy, black

Set pointer: upper and lower limits are in red and green, while others are in red. Instrument panel: aluminum alloy, with black letters on a white background

Glass: Organic glass (safety glass optional) Protection level: IP54, IP65

Contact switch:

YXH magnetic auxiliary contact

No control unit and additional power supply required

Can directly switch loads of 220V and 1A

Up to 4 sets of contact switches can be equipped

YXG inductive electrical contact

Explosion proof ExibicT6

Non contact sensor with long service life

Need to be used in conjunction with safety barriers

A switch that ensures fault safety at high switching frequencies

Up to 2 sets of contact switches can be equipped

YXHD magnetic spring type electrical contact

No control unit and additional power supply required

The contacts are not easily oxidized and have a long service life.

Up to 2 sets of contact switches can be equipped

Maximum voltage 24V, contact power 10W

option

Up to 4 electrical contact switches

Assembly of diaphragm seals

Instrument filling: instrument specific oil

Radiator (can adapt to higher medium temperatures)

Dual range dial

Panel installation

Diaphragm measurement: measuring range less than 0.1MPa

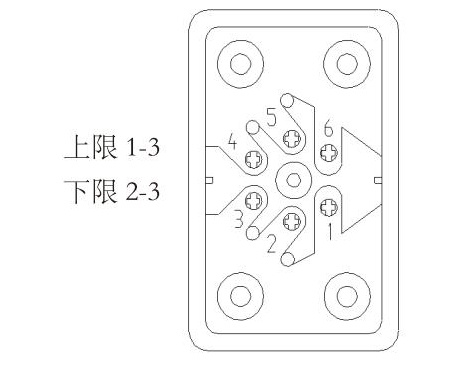

Technical parameters of YXG induction electric contact

Rated voltage: DC8V, safe use voltage not greater than DC16V

Switching power: 30VA

Working current: on state>3mA, off state<1mA, safe use of Shenliu

Less than 52mA

Switching frequency: less than 5000Hz

Explosion proof grade: Exibi CT6

Contact adjustment range: 10%~75% of the recommended full range

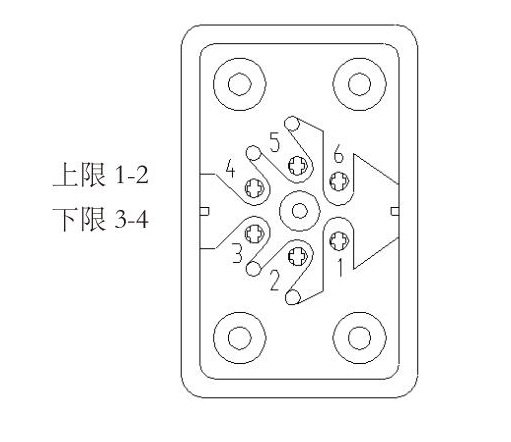

Wiring diagram:

Technical parameters of YXH type magnetic auxiliary electrical contact

Rated voltage: AC380V or DC220V

Optional: Gold contact 24V

Switching power: 30VA

Maximum current: 1A

Contact adjustment range: 10%~75% of the recommended full range

Contact material: silver nickel alloy (or gold plated optional)

Wiring diagram:

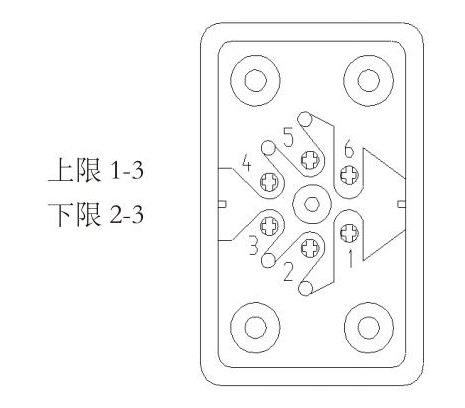

Technical Parameters of YXHD Magnetic Spring Electric Contact

Rated voltage: 24V

Switching power: 10W

Maximum current: 1A

Contact adjustment range: 10%~75% of the recommended full range

Wiring diagram:

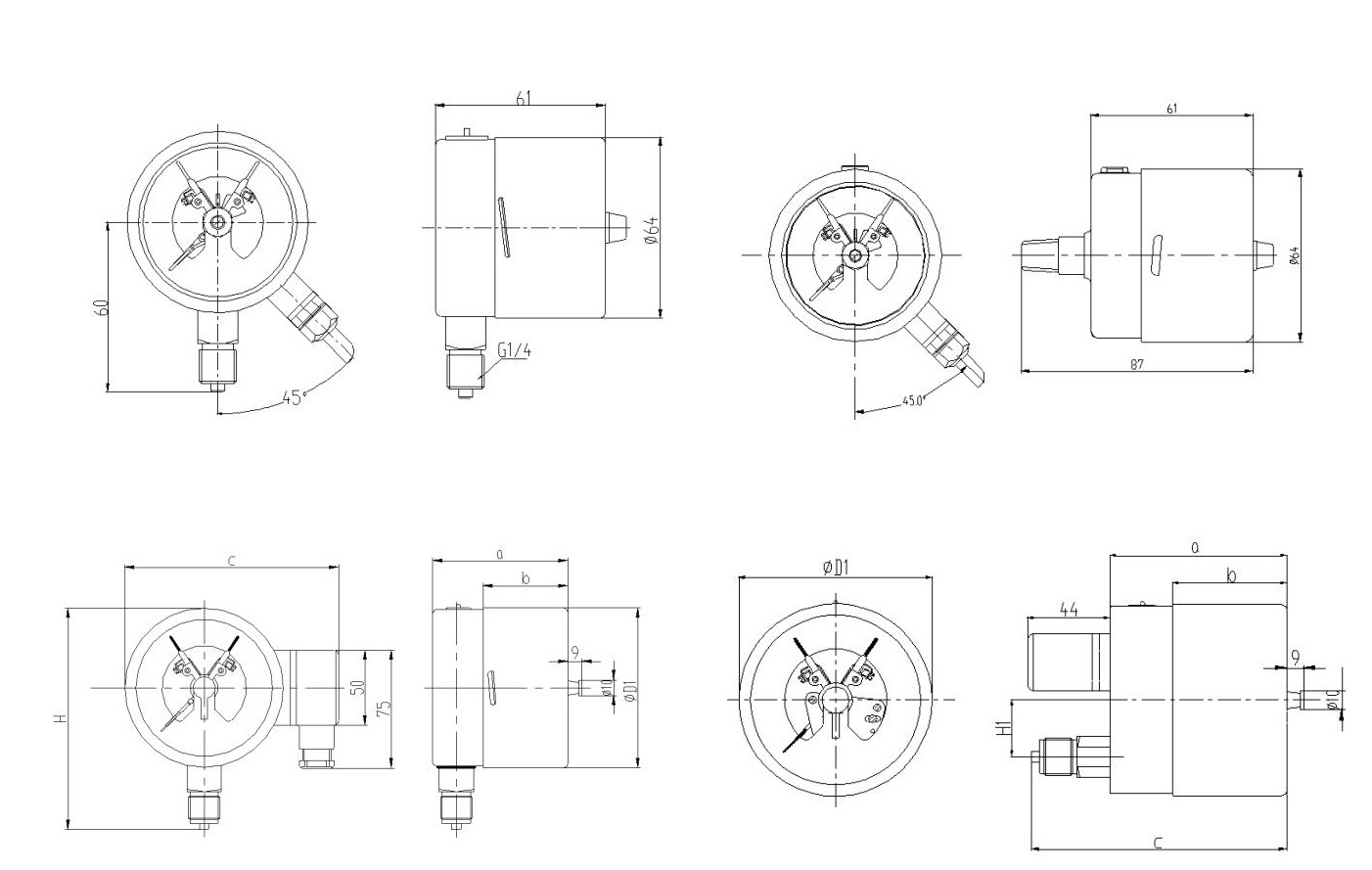

| Nominal | Size mm Contact type | D1 | a | b | C | H |

| F100 | Single or double contact | 101 | 88 | 55 | 130 | 30 |

| Three-contact | 101 | 95 | 62 | 137 | 30 | |

| Four-contact | 101 | 109 | 76 | 151 | 30 | |

| F150 | Single or double contact | 150 | 88 | 55 | 136 | 46 |

| Three-contact | 150 | 95 | 62 | 143 | 46 |

| Nominal | Size mm Contact type | D1 | a | b | C | H |

| F100 | Single or double contact | 101 | 88 | 55 | 130 | 30 |

| Three-contact | 101 | 95 | 62 | 137 | 30 | |

| Four-contact | 101 | 109 | 76 | 151 | 30 | |

| F150 | Single or double contact | 150 | 88 | 55 | 136 | 46 |

| Three-contact | 150 | 95 | 62 | 143 | 46 |

| Nominal diameter | Size mm Contact type | D1 | D3 | D4 | a | b | C | H |

| F100 | Single or double contact | 101 | 118 | 132 | 88 | 55 | 130 | 30 |

| Three-contact | 101 | 118 | 132 | 95 | 62 | 137 | 30 | |

| Four-contact | 101 | 118 | 132 | 109 | 76 | 151 | 30 | |

| F150 | Single or double contact | 150 | 165 | 180 | 88 | 55 | 136 | 46 |

| Three-contact | 150 | 165 | 180 | 95 | 62 | 143 | 46 |

| YX | Electrical contact pressure gauge |

| H contact type | H: All steel magnetic assist type G: All steel induction type HD: All steel reed type |

| N Oil-filled | N: Earthquake-resistant type None: Normal type |

| 100 nominal diameter | 63:Φ63mm 100:Φ100mm 150:Φ150mm |

| AO installation method | AO: Radial Edgeless ZO: Central Axial Edgeless ZT: Central Axis Forward BO: Lower Axial Edgeless BT: Lower Axis Front |

| 531 Housing type | 521: Stainless steel internal card mounted type 531: Stainless steel internal card welded type |

| M120 range | See Appendix 1, Quantum Code Table, for details |

| M20 | See Appendix 2 Thread Code Table for details |

| Way Other options | See Schedule 3 Additional Options Table for details |

Related Products

Leave us a message